AUTOMATED INSPECTION SYSTEM FOR ADHESIVE BEADS

The Challenge

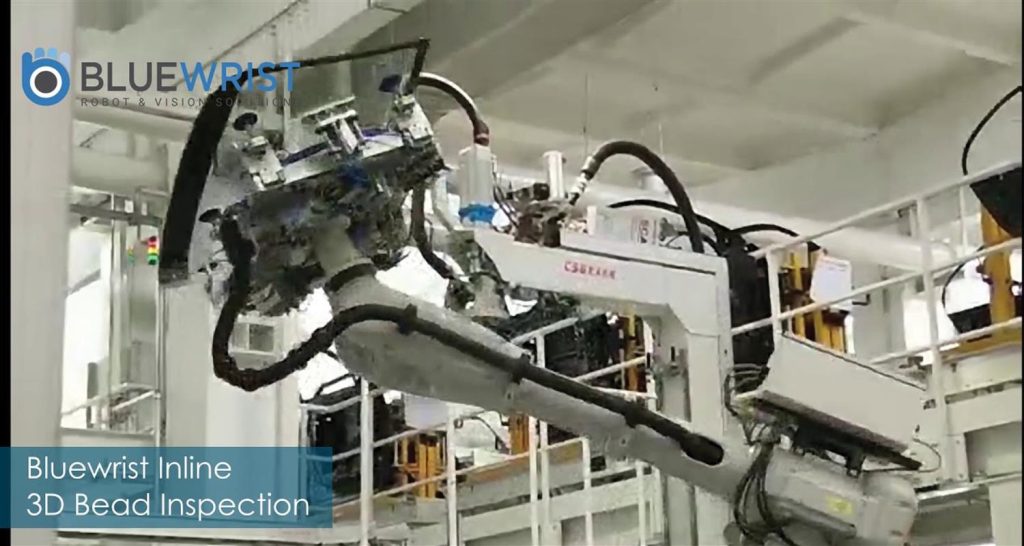

A global Tier-1 automotive supplier requires an automatic robotic and 3D vision system to inspect an engine cover RTV (room-temperature vulcanizing) bead for defects.

The RTV adhesive bead creates a seal between the engine cover to prevent leaks during operation. The correct and consistent volume of RTV bead applied is critical to ensure a correct seal to prevent leaks that can lead to potential recalls. The customer’s specifications included checking for the width, height, and continuity of the bead. Because of the height requirement and the color of the bead, a 2D or manual inspection process was not possible because it would not provide the accuracy needed to inspect the consistent amount of RTV bead application.

The choice of a 3D camera system was important to prevent noise caused by the shiny machined surface of the part. Furthermore, the system needed to be fast enough to process the data within a few seconds and return the pass/fail information to the line PLC.

The Solution

A global Tier-1 automotive supplier requires an automatic robotic and 3D vision system to inspect an engine cover RTV (room-temperature vulcanizing) bead for defects

The RTV adhesive bead creates a seal between the engine cover to prevent leaks during operation. The correct and consistent volume of RTV bead applied is critical to ensure a correct seal to prevent leaks that can lead to potential recalls. The customer’s specifications included checking for the width, height, and continuity of the bead. Because of the height requirement and the color of the bead, a 2D or manual inspection process was not possible because it would not provide the accuracy needed to inspect the consistent amount of RTV bead application.

The choice of a 3D camera system was important to prevent noise caused by the shiny machined surface of the part. Furthermore, the system needed to be fast enough to process the data within a few seconds and return the pass/fail information to the line PLC.

INSPECTION RESULTS

In automatic mode, ScanXtream will send the inspection result (pass/fail) with coordinates of the failing checking points to comXtream for reporting purposes. However, within ScanXtream, the user can visualize the current or previous inspection results.

Call RAM Solutions for more info or a demo at 248-299-0525.

Download this case study of the Bluewrist 3D Bead Adhesive Inspection